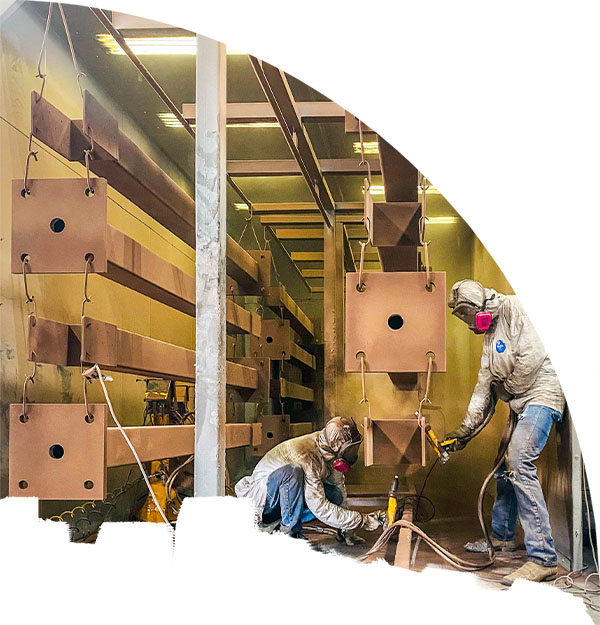

Powder Coating Process

The powder coating process includes: sandblast, prime, and powder coat. These three steps ensure that your product will be protected from outdoor exposure, scratches, chips, and more.

At Smith Powder Coating, we strive to provide the highest-quality powder coating in the Utah County area. We have years in the industry and understand the importance of the three-step powder coating process. Our method ensures that the metal product will be resistant to chips, scratches, flakes, and scuffs. Powder coating will also protect the metal from rust, corrosion, and sun fade. Learn more about our powder coating process below.

Three-Step Powder Coating Process

Step 1: Sandblast

First, the metal product is sandblasted to a pure white finish. This high pressure blasting removes all impurities from the metal including: old paint, rust, and oil. Sandblasting also creates a profile on the surface (similar to sandpaper), which helps the epoxy prime better adhere to the metal.

Step 2: Primer

Second, an epoxy primer is applied to the metal product. Once the metal surface is fully coated, the product is baked at 400 degrees. This allows the primer to melt deep into the profiled metal.

Outdoor products (including site furniture, business signs, and railing) will not hold up without primer.

Step 3: Powder Coat

Third, polyester powder coat is applied to the metal. Our durable powder ensures that the coating will hold up against everyday use, UV sun rays, cracking, and more. Once again, the product is baked at 400 degrees. After the metal has cooled, you will be left with a smooth, strong finish.

Why Choose Smith Powder Coating In Utah County?

Above all, we care about our customers. We work hard to create a positive experience at Smith Powder Coating. For example, each job is done quickly and efficiently. Our staff is friendly and provide great customer service.

Powder Coat Durability:

How durable is powder coat? Powder coat is considerably harder than the average paint and twice a thick. When applied to metal, powder coat creates an impermeable barrier. This keeps the metal free from rust and corrosion. Powder coated products will hold up for years to come without sign of wear. Click here for more powder coating benefits.

What Can Be Powder Coated?

From aluminum rims to site furniture. Our team powder coats it all! Wonder if your product can be powder coated? Feel free to give us a call at (385) 200-1260 and receive a free quote. Click the button below to view more examples of what we powder coat.

Park Benches

Park Benches shine with a powder coat finish that is water and sun repellent. You can view all our color options here.

Business Signs

Powder coated signs make your business standout. Choose classic bronze, vibrant blue, or any shade in between.

Start With a Free Quote

Let’s Get Powder Coating

Call: (385) 200-1260