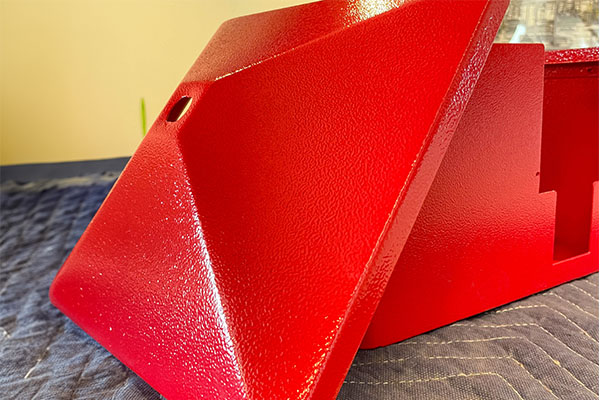

Powder Coated Candy Dispenser Parts

Gum ball machines are tricky to keep looking nice and clean. With powder coated candy dispenser parts your machine won’t chip, peel, or scratch. This option is much safer than liquid paint and will last much longer. Keep your vibrant red looking red for years to come!

Come visit Smith Powder Coating in Spanish Fork today for any of your powder coating needs!

Our Three Step Process

Sandblasting

We first sandblast the surface to create a white metal finish. We shoot a mixture of pressurized sand and air over the entire product. This cleans the metal and removes any old paint or rust.

Primer

Next, we coat the entire surface in a thin epoxy primer. This step is crucial for any outdoor products. We then place it in a 400 degree oven. This curing process helps the primer bond deep into the metal.

Powder Coat

Finally, we coat the metal in a powder coat with an electrostatic spray gun. This can be done in any color or texture you desire. We again place it in the oven to cure. Our durable powder will hold up against the sun, rain, and snow.

Benefits to Powder Coating

Choose Smith Powder Coating

Not all powder coaters are the same, and many don’t go through the precise steps and details like we do. At Smith Powder Coating, it is our mission to create the highest quality effort. Call us today at (385)-200-1260 for any of your powder coating projects or questions!