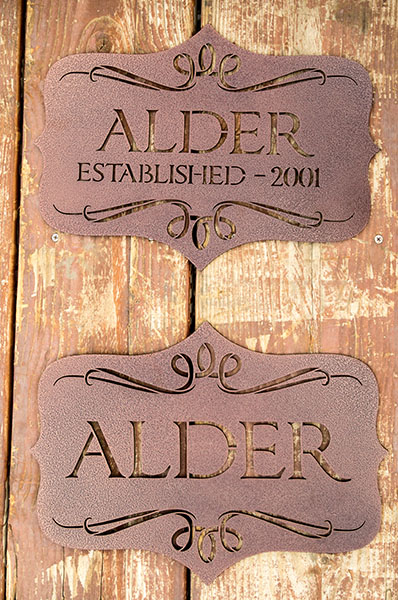

Powder Coated Name and Address Signs

Powder coated name and address signs stay resistant and vibrant looking because of the protection layer. The powder coating helps protect against harsh weather conditions and sun fading. Powder coating is more durable than liquid paint because after time the liquid paint will chip and look worn, but the powder coat will still stay looking as perfect as it did the day it came out of production.

Powder Coated Bench Name and Address Signs Process

First, you will drop the address sign off at our facility. (You can order a laser cut metal sign here) The sign will then be sandblasted, primed, and powder coated. This three-step process is crucial for the longevity of the finish.

Metal sign exterior is sandblasted to a white metal finish. This creates a profile that helps the primer and powder coat adhere to the surface. Sandblasting also removes impurities including: rust, old paint, and oil spots.

Primer is applied to the sign next and cured at 400 degrees. Thanks to sandblasting, the primer will be in every crevice of the metal. This protects the bare metal.

Super durable powder coat is applied to the metal. It is also cured at 400 degrees to melt deep into the metal. Once cool, the powder coated name and address signs will be protected from rust and corrosion.

Benefits of Powder Coated Name and Address Signs

Powder coating provides a long-lasting, vibrant finish to the name and address signs.

Environmental Process

Powder coat is an environmentally friendly process that doesn’t release VOC’s into the atmosphere. The overspray is also collected and reused on future projects.

Durable Finish

Powder coated signs have a tough surface that is resistant to chips and scratches. This keeps the bare metal safe from rust, corrosion, and outdoor exposure.

Color Selection

Smith Powder Coating uses durable, high-quality powder coat that is available in a large selection of color options. You can view the powder coat colors here.